When renting generators, it's important to know OSHA requirements for jobsites. There are two specifications: dealing with grounding the generator and bonding the neutral to the frame.

When renting generators, it's important to know about OSHA requirements for units on constructions sites. There are two specifications: one, dealing with grounding the generator, and two, with bonding the neutral to the frame. Wire Wound Rheostat Resistance

For starters, the term "ground" refers to a conductive body, which is typically the earth. The act of "grounding" means creating a low-resistance path between an electrical circuit or equipment to the earth. So, grounding is the intentional connection between the neutral wire and the grounding means of the generator, which includes its frame. The term "bonding" is also used to describe the intentional electrical connection of components such as the gas tank or engine to the frame of the generator.

According to the OSHA's grounding requirements for portable and vehicle-mounted generators, the first step in proper grounding is maintaining and operating generators in accordance with the manufacturer's use and safety instructions.

A portable generator should never be attached directly to the electrical system of a structure, like a house or trailer, unless the generator has a properly installed open-transition transfer switch. This is key to proper and safe use, as proper grounding and bonding prevent shocks and electrocutions.

Continuing on, the OSHA guidelines state that for portable and vehicle-mounted generators, the frame of a portable generator does not need to be connected to the earth and can instead serve as the ground in place of the earth, provided the generator supplies only equipment mounted on the generator and/or connected using receptacles, and the equipment is grounded through the receptacles to the frame of the generator. This can also include a ground rod.

Note that the generator’s noncurrent-carrying metal parts — like the fuel tank, the internal combustion engine, and the generator’s housing — must also be bonded to the frame. The equipment grounding conductor terminals (of the power receptacles that are a part of the generator) are also bonded to the generator frame.

Generators used on construction sites supplying cord-and-plug connected equipment (tools, lights, etc.) are considered a “separately derived system” in the National Electrical Code, and thus, the neutral must be bonded to the frame of the generator.

In some cases, standby generators are not required to have an electrical bond from the neutral to the frame. These so-called "floating neutral generator" applications occur when connecting to a recreational vehicle or to home power where the transfer switch does not change the neutral to ground connection. When used as a stand-alone floating neutral generator, at least the frame of the generator must to be bonded to earth ground. This involves putting a rod into the earth and attaching a ground cable from the rod to the generator frame. Standby generators must be connected thorough transfer switch and must be installed by a qualified electrician in accordance with article 250 of the National Electrical Code.

For operator safety, the grounding and bonding circuits must provide a low resistance connection and must be capable of conducting a surge of electrical current.

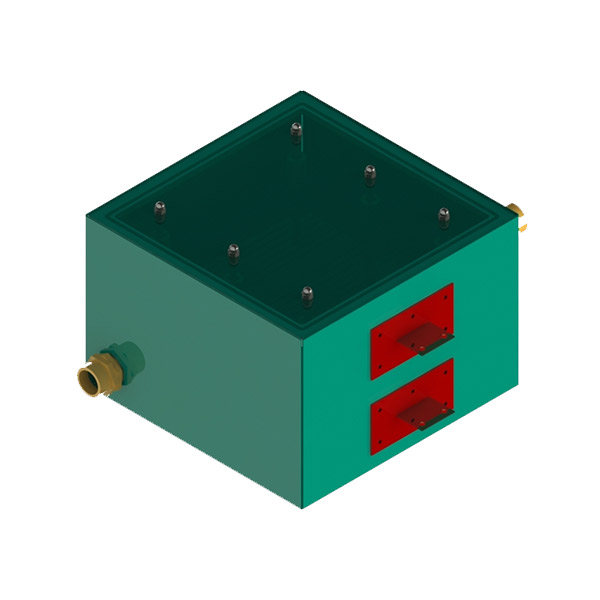

Rental companies can use a ground/neutral continuity tester for portable generators. It tests the integrity of the ground and neutral connections from each of the receptacles to the frame of the generator. The test is conducted at a full 10 amperes of current and tests for a resistance of 0.2 ohms or less. A panel-mounted meter monitors the current flow. Adapters are offered to match all standard receptacles.

An ohmmeter won't suffice, as it will indicate if there is an electrical connection, but it can't tell you if the connection is a single strand of wire or a solid connection. Remember, you are depending on the bonding connection to conduct a surge of current if a short circuit should occur.

First, the generator should be given a visual inspection. Always consider the following questions:

Next, the generator should be tested for the following:

While that might seem like a lot of trouble to go to, it's preferred over using a voltmeter, which is like trying to judge a car's performance by just racing the engine on the side of the road. If you want to provide your customers with quality products they can depend on, you need to inspect them, test them, and document the results. The future of your company depends on the quality of the service you provide your customers.

This piece originally ran in 2014 and was updated on June 18, 2021.

Marc Sotcher, president of Sotcher Measurement Inc.

The company has been furnishing electrical safety products, consulting and safety training to rental companies for over 40 years. Sotcher Measurement offers a full line of electrical safety products including leakage current testers to verify the safety of electrical equipment, service tags that offer you liability protection by documenting the inspections and tests performed, generator test sets to verify the performance of generators, ground bond testers, Hi-pot testers, power cord testers, and a wide range of custom designed automatic test sets.

Does Sotcher Measurement offer a product for that purpose?

Yes, we do. We offer a 10, 15 and 30 KW Generator Test Sets (Load Banks) that allows the full load testing of 120 and 120/240 volt generators. The test sets are in common use throughout the rental industry, Honda Service Centers, and most generator service facilities.

What if the generator has had electrical service performed on it?

If any electrical service has been performed on the generator, a Hi-Pot (dielectric strength) test should be performed to detect any marginal points in the insulations.

Low Resistance Grounding Resistors Diesel-driven units are subject to particular malady known as "Wet Stacking" or "Slobbering" that stems from operation under no-load or light-load conditions. Such operations cause fuel deposits to collect on the combustion chamber, injector nozzles, piston rings, turbo-charged and exhaust system. The result is diminished engine output capacity. Fully loading the generator for a time period will clear this condition.