Every product is carefully selected by our editors. If you buy from a link, we may earn a commission.

Before "lume," glowing watches were radioactive. Glow Sheet

You don't need to be a watchnerd for a glow-in-the-dark watch dial to elicit a childlike sense of delight. But watchnerds are especially into their "lume." That's the term they use for the luminescent material that keeps their watches legible in the dark, and it's all but essential to any sport watch. While some will debate what brand has the strongest lume game, there's also some interesting science behind it, different methods of illuminating a dial — and some surprising history.

In the 1910s and ’20s, a working-class woman could make a decent living painting luminous material onto watch dials. It was a glamorous gig that required artistry and skill. The tech was cutting-edge at the time, and with the need for legible watch dials for soldiers during WWI, workers could take pride in helping the war effort. The luminous material was painted on with a brush that was kept sharp by pointing the bristles with the tongue. Workers also began to paint their fingernails with the glowing substance. The material in question: radium, which, when mixed with zinc sulfide (a phosphor) produced a bright glow.

Employers told the women there would be no ill effects from ingestion and exposure to the material, despite the fact that factory owners and scientists did take precautions when handling larger quantities of radium. But when workers began suffering from anemia, bone fractures, necrosis of the jaw, and eventually death, it became clear these women were misled.

By 1927, dial painter Grace Fryer and a handful of other women — known as the “Radium Girls” — sought compensation from the United States Radium Corporation, a major employer of dial painters in the U.S. The silver lining to all this was that litigation paved the way for increased legal protection of workers in the U.S. and further tightening of industrial safety regulations.

The usage of the material was then greatly scaled back. By the 1960s the amount of radium used in watch dials was approximately one-hundredth the amount used in the early 1900s; in 1968 it was banned altogether.

Another radioactive material, tritium, arose as a successor. Tritium operates under the same chemical principles as radium — the material undergoes decay, releasing electrons that trigger zinc sulfide to glow. Tritium, however, is significantly less radioactive than radium, meaning it was safe enough to be painted onto watch dials for decades, until the early 1990s when a couple of even safer alternatives — still used today — took its place.

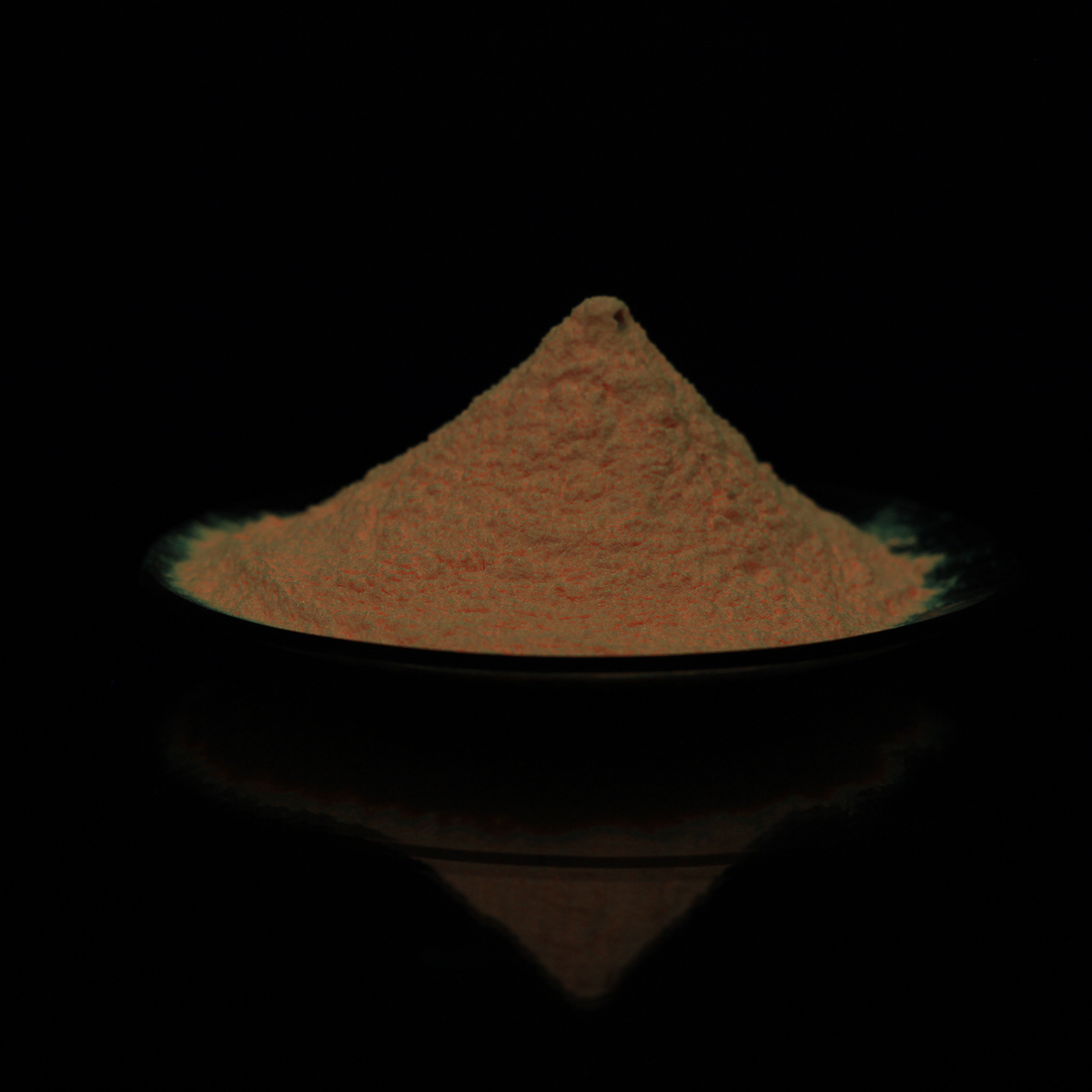

Pigments based on photoluminescent material (like strontium aluminate) are most commonly used for watch lume today. This non-radioactive material is painted onto hands, numerals and dials, then glows in the dark (in usually a green or blue hue) by absorbing and then re-emitting light.

The downside, compared to radioactive materials, is the longevity of the glow in the absence of light — it usually only lasts about seven hours in darkness. Swiss brand Super-LumiNova, founded in the early ’90s, brought the method into the mainstream and today is one of the largest suppliers, though some watch manufacturers, like Seiko and Rolex, produce their own proprietary variants.

Tritium has made a comeback of sorts, though not as a paint. Essentially, tritium in gas form is encapsulated in borosilicate glass that has been internally coated with a phosphor layer. The tritium gas undergoes beta decay, which releases electrons, causing the phosphor to glow. Though still radioactive, the gas poses little to no risk in the tiny amounts found in tritium tubes, and they're safely enclosed in glass.

A handful of watchmakers are known today for using tritium gas tubes, like Ball, Luminox and Marathon — specifically for tool watches, because their luminescence doesn’t fade away after a few hours like Super-LumiNova. However, with a half-life of just 12 years, after about 24 years only a quarter of the radioactive material is left; thus, just as lume ages, tritium gas tubes will also eventually require replacement.

Electroluminescence is the production of light as a result of an electrical current passing through a phosphor. In a watch, a glass or plastic panel is coated with an electric conductor and a phosphor, then mounted behind the dial. At the press of a button, an electric current is delivered, causing the phosphor to react, acting as a backlight.

Luminous Stair Step Markers Though this approach is most commonly found in battery-powered digital watches, Timex’s Indiglo is the most famous use of this type of luminescence in an analog watch. The company patented the technology in 1992, making Timex one of the few producers of analog watches with this type of tech; other affordable quartz timepieces from Bertucci to Casio use it as well.